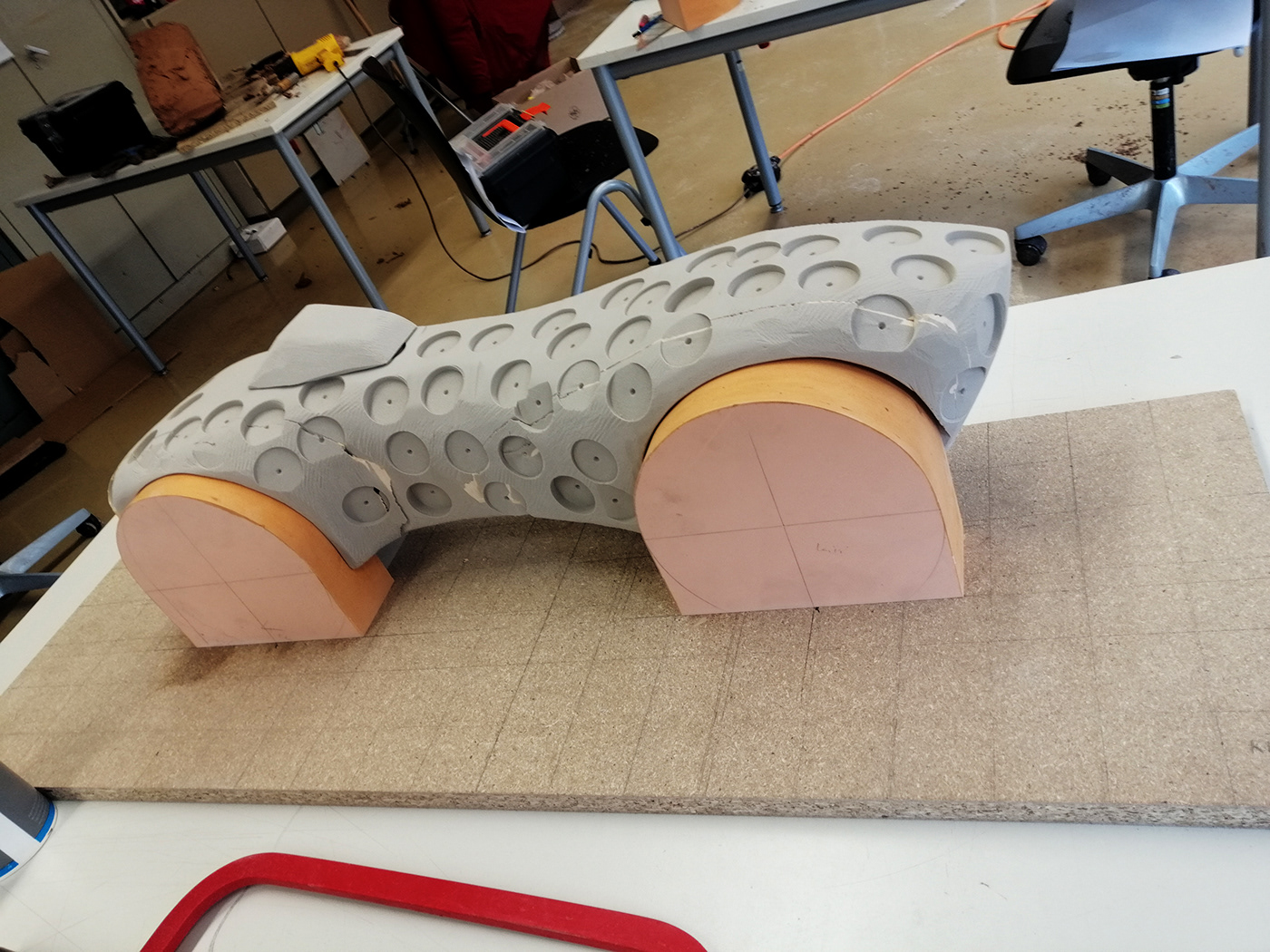

The first step is a foam model that is about 3 cm smaller than the final clay model.

This serves as a basis for better adhesion of the clay and less material wastage.

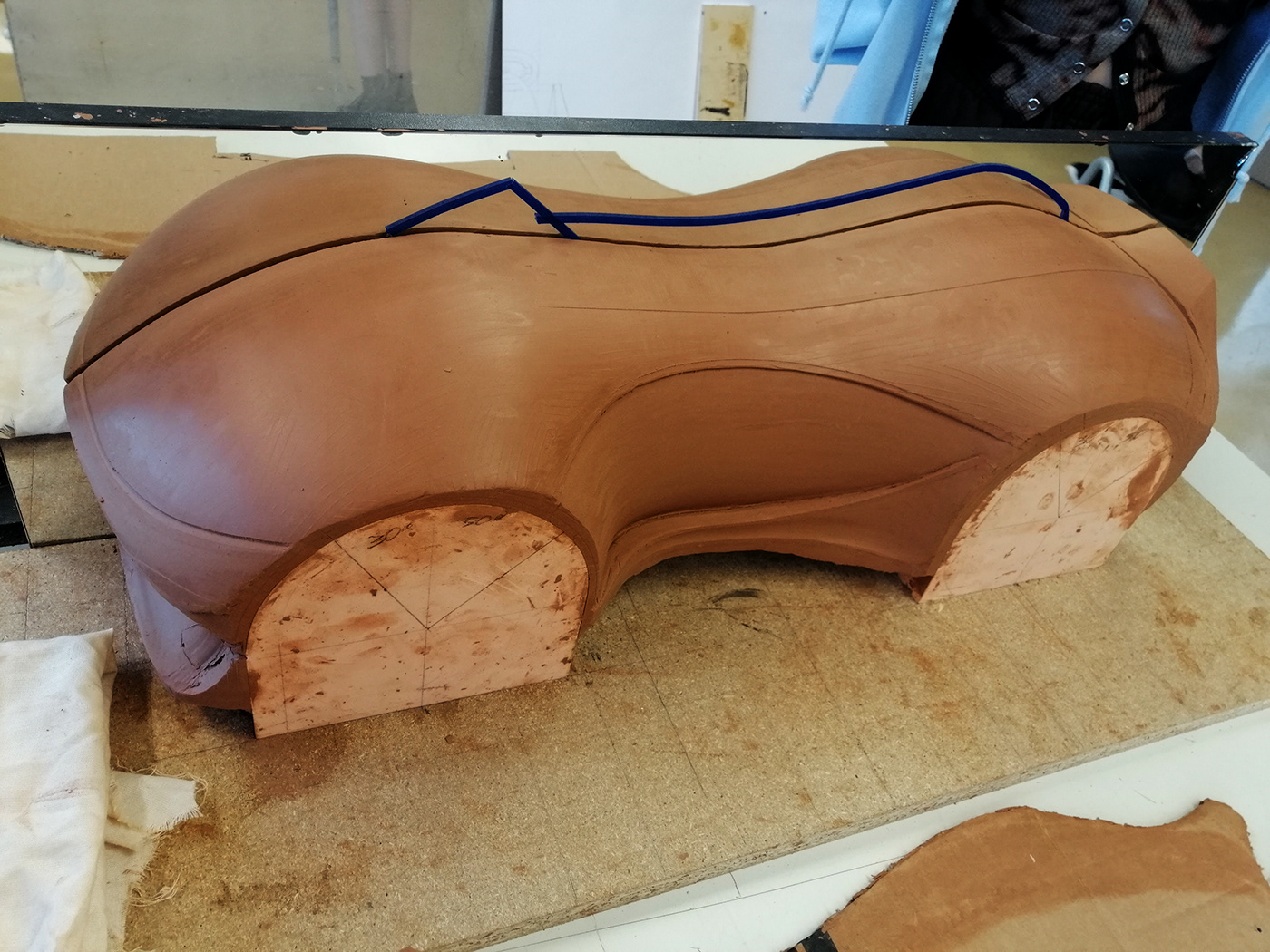

Next comes the clay application and rough modelling. This is how the basic form is made.

This is followed by more rough modelling to building up the most important areas with a Serrated Edge Steel Clay Scraper.

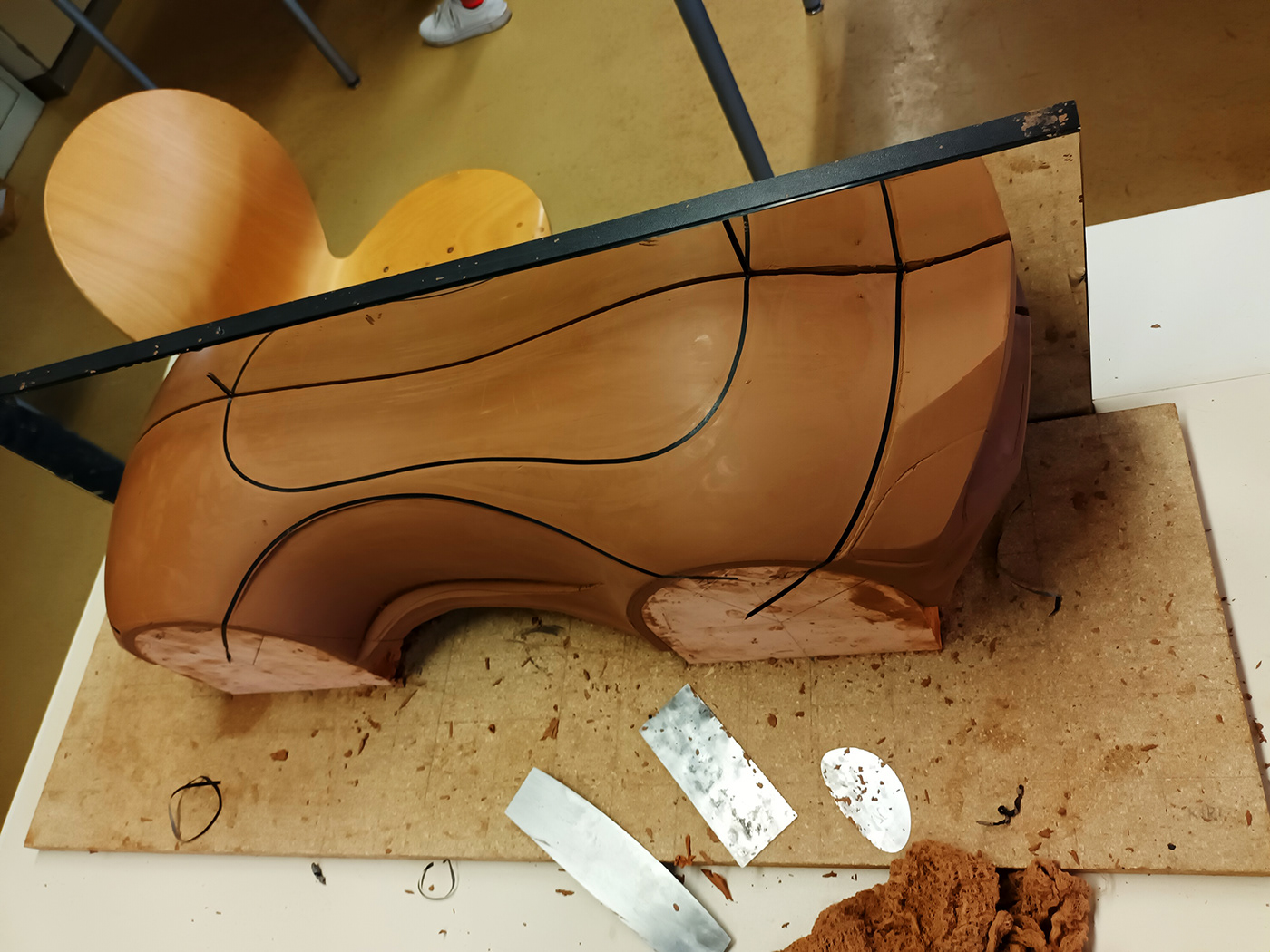

The first lines and edges are created on the model with the help of tapes.

The taping is important throughout the entire process to define lines and separate components.

Bobbycar Clay-Model

The most extensive clay school project to date.

It was a long way from the initial sketches to designing my own bobby car and i loved working on it.

The seat is removable and interchangeable with other variants.

the shoulder line inspired by nature and the soft shapes of the siamese combat together with the convex side surface and the curved hips results in a harmoniously soft body.

The side walls, as well as the headlights / taillights and the spoilers at the front / rear are made of a soft material.This minimizes the risk of injury in the event of an impact. Also, no paint is scratched in the event of a collision.

In addition there are the multi-part rims with ball bearings and fulda tires, which can be found in another project here on behance.